In the fast-evolving world of industrial innovation, digital twins have become a critical asset for achieving operational excellence. When paired with the Internet of Things (IoT), digital twins offer organizations a powerful way to replicate, monitor, and optimize real-world systems in real time. This transformative synergy is redefining the future of Smart Industry, where simulation, predictive maintenance, and risk mitigation empower smarter, faster decisions-making.

With platforms like OneMind NG, companies are now equipped to implement digital twins at scale—bridging the gap between the physical and digital worlds for unparalleled control and insight.

What Are Digital Twins?

A digital twin is a virtual model that mirrors a physical asset, process, or system. Connected through real-time data streams, it reflects the live status, behavior, and performance of its physical counterpart.

Beyond Static Models: Real-Time Replication

Unlike traditional simulations, digital twins continuously update using real-time input from IoT sensors and devices. This dynamic reflection allows operators to:

- Monitor asset health

- Forecast failures

- Simulate “what-if” scenarios

- Make proactive decisions

IoT: The Backbone of Digital Twins Functionality

IoT plays a critical role in enabling digital twins. Without real-time data collected from connected devices, digital twins would remain theoretical models with limited application.

Live Data = Live Insights

IoT sensors embedded in equipment or infrastructure feed operational data into the digital twin. This real-time connection empowers businesses to visualize current states, predict future behavior, and automate responses.

For example, in a factory setting, IoT devices can monitor variables such as temperature, pressure, and energy consumption—enabling the digital twin to recommend immediate adjustments or detect anomalies before they impact operations.

Key Benefits of Using Digital Twins in Industry

Integrating digital twins into industrial environments delivers measurable improvements in performance, safety, and strategic planning.

1. Predictive Maintenance and Cost Reduction

Digital twins detect irregular patterns before they lead to costly failures. This allows companies to perform maintenance only when necessary, minimizing unplanned downtime and repair costs.

2. Operational Optimization

By virtually simulating changes before implementing them, businesses can test process improvements and reduce trial-and-error risks on the production line.

3. Enhanced Risk Management

Digital twins can simulate failure scenarios, enabling teams to identify vulnerabilities and prepare contingency plans in advance.

4. Sustainability Gains

With accurate data, organizations can monitor energy consumption, reduce waste, and align with ESG goals—supporting greener, more responsible operations.

How OneMindNG Enables Real-Time Digital Twins Solutions

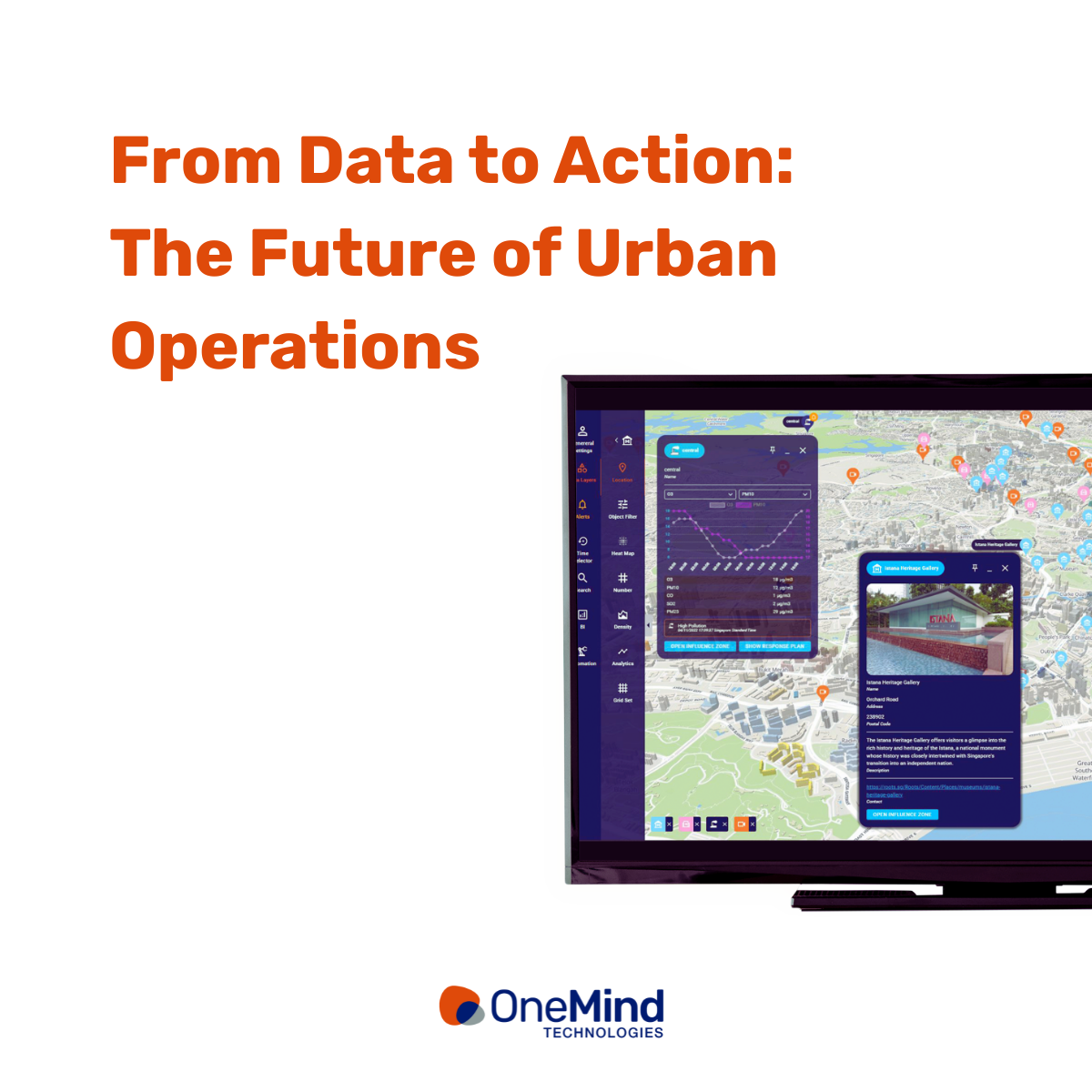

OneMindNG stands out as a comprehensive platform that integrates IoT data, analytics, and visualization—making it ideal for digital twin implementation.

Unified Visualization and Control

With OneMind NG, organizations can visualize digital twins of assets or environments through intuitive dashboards. Whether monitoring a power plant, logistics hub, or smart building, users receive instant feedback and actionable insights to support faster, more informed decisions.

Custom Alerts and Scenario Simulations

The platform supports customized alerts, automated responses, and scenario simulations. This allows users to test potential actions before implementation,maximizing control while minimizing disruption.

Real-World Application: Digital Twins for Facility Management

A major industrial client integrated OneMind NG with hundreds of IoT sensors to create a digital twin of its production facility. The platform tracked machine performance, environmental conditions, and energy consumption in real time. Over six months, the client achieved:

- A 35% reduction in unplanned downtime

- A 20% increase in energy efficiency

- Faster, more confident operational decision-making

Conclusion: The Future Is Real-Time, Virtual, and Intelligent

As industrial operations become more complex, the ability to simulate and optimize them in real time is no longer optional—it’s essential. Digital twins, powered by IoT and intelligent platforms like OneMind NG, are transforming how businesses monitor, plan, and scale. They enable a future where decisions are data-backed, risks are minimized, and innovation is continuous.

Curious about how digital twins can revolutionize your industry?

👉 Visit www.onemindng.com to explore solutions or request a tailored demo here.