The rise of Smart Industry 5.0 marks a new phase in industrial evolution—one where technology and human ingenuity work side by side. At the center of this transformation is the Internet of Things (IoT). By enabling real-time connectivity between machines, systems, and people, IoT is redefining how industries operate, adapt, and thrive in a digital-first world.

As manufacturers and operators embrace Industry 5.0, the focus shifts from pure automation to intelligent collaboration. Platforms like OneMindNG are helping lead this charge by offering integrated, scalable solutions powered by real-time data and IoT connectivity.

What Is Smart Industry 5.0?

Smart Industry 5.0 builds upon the automation and efficiency of Industry 4.0, adding a new layer of human-centric innovation. It emphasizes personalization, sustainability, and resilience—empowered by digital technologies such as:

- IoT (Internet of Things)

- Artificial Intelligence (AI)

- Robotics

- Edge and cloud computing

- Real-time analytics

From Automation to Augmentation

Instead of replacing workers, Industry 5.0 enhances human capabilities. Operators are now empowered with real-time insights and intelligent systems that support safer, more informed decision-making.

Key Benefits of Industry 5.0

- Personalized production

- Enhanced safety and ergonomics

- Greater sustainability and energy efficiency

- Faster response to market changes

The Role of IoT in Industry 5.0

IoT is the backbone of this new industrial paradigm. It provides real-time visibility into equipment status, production processes, and environmental conditions.

Connecting the Factory Floor

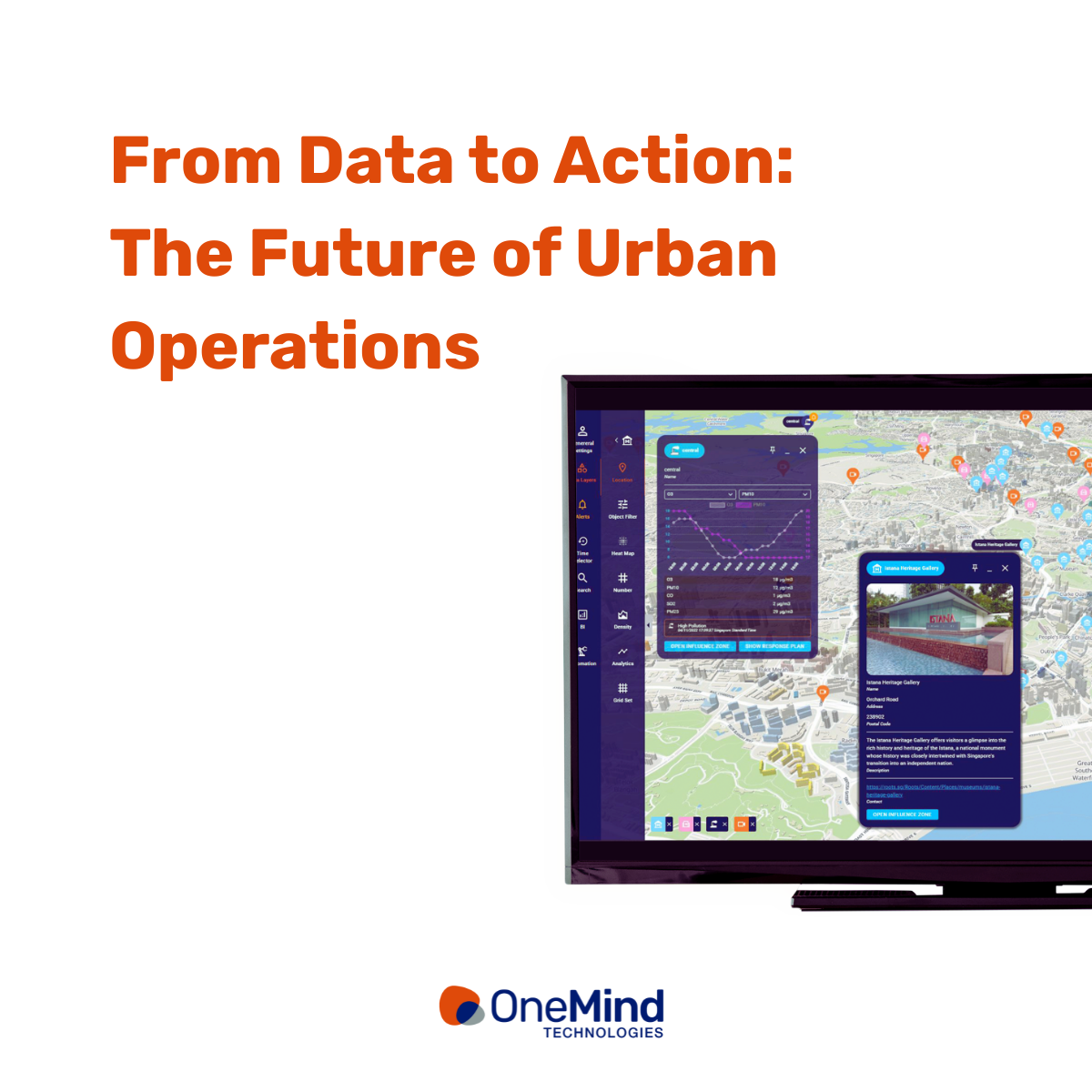

IoT devices collect data from machinery, logistics systems, and even wearable tech. This information feeds into intelligent platforms like OneMindNG, which present it through intuitive dashboards for quick analysis and action.

Data-Driven Decision Making

Real-time data allows for predictive maintenance, quality control, and resource optimization. This reduces downtime, minimizes waste, and boosts operational performance.

OneMind NG: Enabling Human-Centric Industrial Transformation

OneMind NG is uniquely positioned to support IoT-driven Industry 5.0. Its modular architecture enables easy integration of IoT devices and systems into a single, unified control platform.

Key Features for Smart Industry 5.0

- Real-time monitoring of industrial environments

- Predictive analytics for maintenance and productivity

- Customizable alerts to support worker safety

- Scalable design for plants of all sizes

OneMind NG empowers plant managers, operators, and engineers to work smarter—with data that’s accurate, timely, and actionable.

Smart Industry 5.0 and the Future of Work

The human element is at the heart of Industry 5.0. IoT doesn’t replace people—it empowers them.

Empowering Operators and Decision-Makers

Wearable IoT tech can track worker fatigue, automate safety checks, and optimize shift planning. Meanwhile, control rooms equipped with real-time dashboards help leaders anticipate risks and seize opportunities.

Creating Resilient, Adaptable Systems

Thanks to IoT and intelligent platforms, businesses can pivot quickly in response to market shifts, supply chain disruptions, or regulatory changes—ensuring long-term resilience.

Conclusion: The Future of Industry Is Human + IoT

As we enter the era of Smart Industry 5.0, organizations must balance automation with human insight. IoT is the key enabler of this balance—creating connected, intelligent systems that make industry safer, more efficient, and more responsive.

With OneMindNG, companies can build smarter factories that are not only technologically advanced but also human-centric.

Discover how OneMindNG can power your Industry 5.0 transformation.

👉 Visit www.onemindng.com to learn more or request a demo here.